Our Products

We’ve created our coatings based on rigorous research. We’ve optimised our formulas, tested and retested.

The result? High-performing products with positive impact.

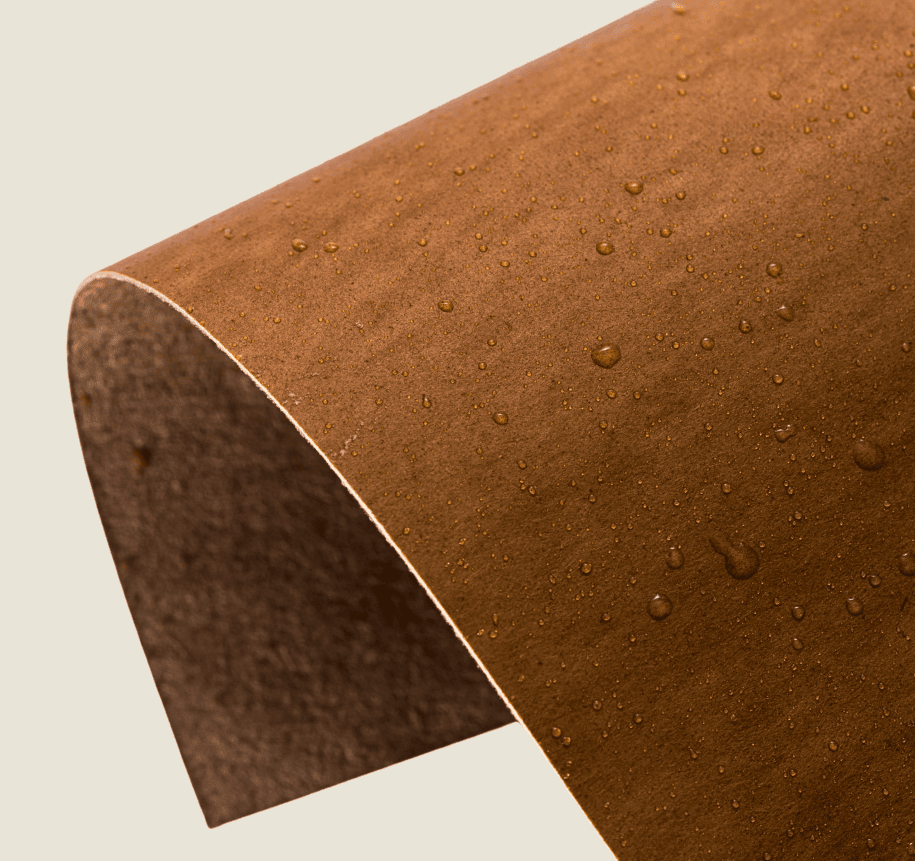

Biobarc™ by Earthodic

Our water-resistant coating.

Biobarc™ protects paper-based packaging from moisture and increases its strength by up to 15%.

It’s carbon content is 100% bio-based and allows the packaging to be repulped and recycled at the end of its life.

Performance Attributes

*coming soonSustainability Attributes

Repulpable

Earthodic coatings allow a high percentage of paper or cardboard fibre to be reclaimed during the repulping process.

So far we’ve achieved 97.1% fiber yield on a standard 205gsm (42#) linerboard. Western Michigan University has tested BiobarcTM according to the Fibre Box Association (FBA) Voluntary Protocol Part I.

Recyclable

The high fibre yield and low sticky count we’ve achieved for repulped BiobarcTM coated products contributes to their recyclability.

Western Michigan University has tested BiobarcTM according to the Fibre Box Association (FBA) Voluntary Protocol Part II.

Compostable*

Unlike some other coatings like wax, compostable coatings allow pulped and paper packaging to naturally decompose into compost.

Our coatings fully broke down in our internal compostability tests. And we’re in the process of getting third-party tests for both home and industrial compostability.

100% Biobased carbon

Our products are made from abundant, renewable bio-based sources like lignin. So no fossil fuels are needed to create them.

All our products are certified as 100% bio-based carbon by the USDA BioPreferred program.

PFAS Free

Our products are free from harmful PFAS chemicals.

They’ve been third-party tested according to the Total Oxidisable Precursor Assay (TOP).

VOC Free

Earthodic products are also free from Volatile Organic Compounds (VOCs) or Hazardous Air Pollutants (HAPs).

They’ve been third-party tested according to EPA Method 24 and Method 311.

Vegan

We don’t use any animal products. And no animals are harmed in the manufacture of our products.

*certifications ongoing

End-products

More and more companies want to improve their environmental impact.

Packaging that goes back into the loop instead of to landfill is a key part of that puzzle.

Our products fit a wide range of applications where barrier properties are needed. Including cold chain packaging and industrial packaging.

Wondering if we can help you?

Industry perspectives

Lars M. Ljung, Sustainability Manager at Planet Protector

Product samples

Order samples of our coatings so you can see them in action. Simply get in touch with us.

Frequently Asked Questions

How does BiobarcTM compare to other coatings for paper?

There are companies on the market that promote the recyclability of their coatings. However, when you dig deeper into their ingredients, they often contain small amounts of plastic to provide barrier properties. So they’re not 100% bio-based like our products.

We believe that being 100% bio-based is important because of the collective need to move away from single-use plastic, which requires the extraction of fossil fuels and causes microplastic pollution.

Bio-based plastics like PLA, which are compostable, are not recyclable.In terms of performance, our liquid water barrier properties exceed that of conventional wax-based coatings. And also increase the strength of the paper substrate.

How do I dispose of BiobarcTM coated paper?

While most coatings have to be disposed of in a specific way, with BiobarcTM, paper can flow through both a natural/regenerative cycle (composting) and a technical cycle (recycling).

So there’s no “wrong” way to dispose of Biobarc.

What can I use BiobarcTM for?

Initial applications include cold chain packaging–boxes that go in and out of cold storage and contain seafood, fresh produce, flowers or plants.

However, any application that requires water resistance is a potential application.

If you’ve got an idea, we’d love to chat and see if we can make it happen.

Can I use BiobarcTM for coffee cups?

Not yet. Our coating does have good water resistance and heat seal characteristics, but the specific requirements for coffee cups can be quite challenging.

We haven’t yet optimised for all these requirements–but we’re working on it. Watch this space!

Does BiobarcTM have oil and grease resistance?

Yes, our coating formulations do offer some oil and grease resistance based on our internal testing.

If you’ve got an application in mind, please reach out and let’s see if we can help.

Does BiobarcTM provide a barrier to water vapour and oxygen?

Please reach out to discuss your exact requirements and whether our coatings are suitable.

Is BiobarcTM heat sealable?

Yes, BiobarcTM does offer heat sealability.

What paper can I coat?

BiobarcTMcan be coated on almost any weight of paper.

Can you coat moulded fibre packaging?

Yes, through different application techniques, it’s possible to introduce Biobarc to moulded fibre packaging.

Are your products patent-protected?

Yes. We hold multiple patents globally for lignin-based coatings, covering both the composition and method of application.

Is BiobarcTM Food Contact Approved?

Not yet. We’re working on it and anticipate having approval by mid-2024.

What methods of application can be used to apply BiobarcTM?

You can apply our coating onto paper packaging using a number of traditional application methods–rod coating, spray, dip coating and more.

Is BiobarcTM commercially available?

We’re currently scaling production, working with toll manufacturers in the US and Asia.

Please contact us if you’d like to receive samples for testing and coating trials.

How much does BiobarcTM cost?

We offer tailored pricing based on your needs. Please get in touch to discuss further.

Do you have a specification or data sheet? How can I get samples and pricing?

We’ll be happy to send you more information on our products–including data sheets, samples and pricing. Simply get in touch!

Contact us

If you’d like to learn more about us or our products, please get in touch.

Whatever stage you’re at in your circularity journey, we’re here to help.

- hello@earthodic.com

- 18 Morrisby St

Geebung QLD 4034

Australia

"*" indicates required fields

- hello@earthodic.com

- 18 Morrisby St

Geebung QLD 4034

Australia