Biobarc™ by Earthodic

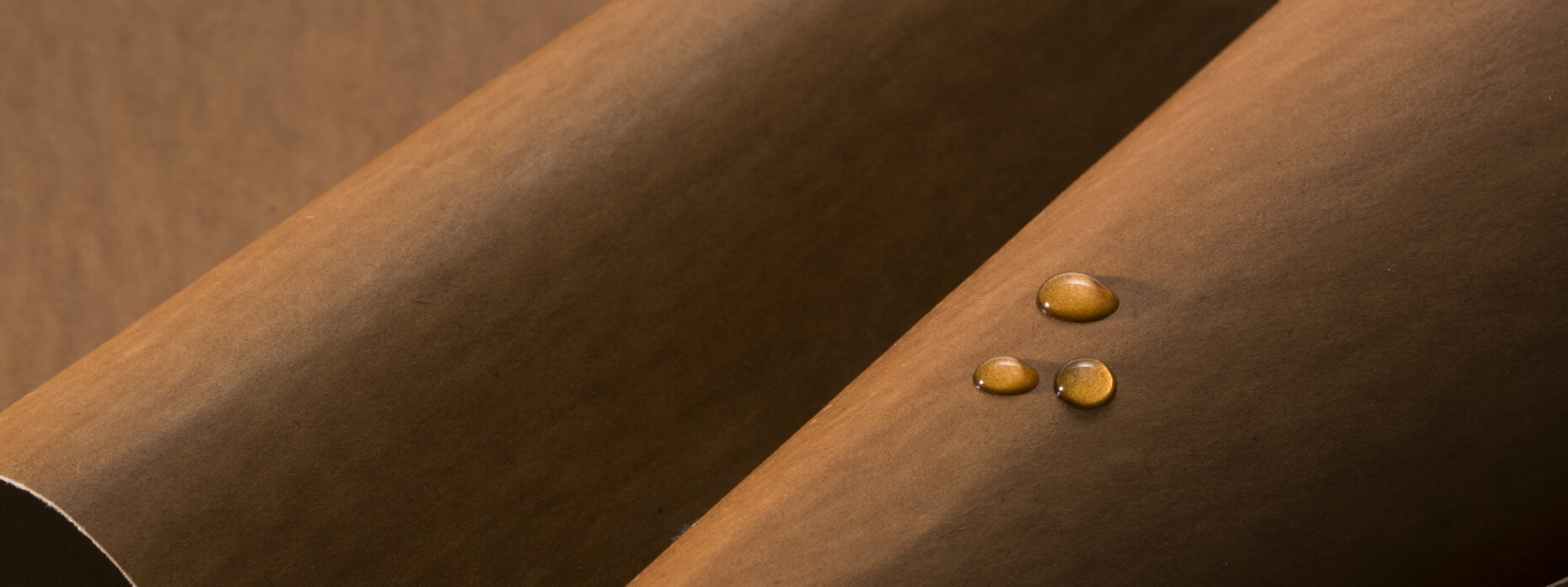

Through diligent research, experimentation and testing, we’ve created Biobarc–a unique bio-based, water-resistant coating.

Our patented product gives pulped and paper products key barrier properties–but doesn’t stop them from being recycled.

Comparison

Performance Attributes

Sustainability Attributes

Repulpable

Earthodic coatings allow a high percentage of paper or cardboard fibre to be reclaimed during the repulping process.

So far we’ve achieved 97.1% fiber yield on a standard 205gsm (42#) linerboard. Western Michigan University has tested BiobarcTM according to the Fibre Box Association (FBA) Voluntary Protocol Part I.

Recyclable

The high fibre yield and low sticky count we’ve achieved for repulped BiobarcTM coated products contributes to their recyclability.

Western Michigan University has tested BiobarcTM according to the Fibre Box Association (FBA) Voluntary Protocol Part II.

Compostable*

Unlike some other coatings like wax, compostable coatings allow pulped and paper packaging to naturally decompose into compost.

Our coatings fully broke down in our internal compostability tests. And we’re in the process of getting third-party tests for both home and industrial compostability.

100% Biobased carbon

Our products are made from abundant, renewable bio-based sources like lignin. So no fossil fuels are needed to create them.

All our products are certified as 100% bio-based carbon by the USDA BioPreferred program.

PFAS Free

Our products are free from harmful PFAS chemicals.

They’ve been third-party tested according to the Total Oxidisable Precursor Assay (TOP).

VOC Free

Earthodic products are also free from Volatile Organic Compounds (VOCs) or Hazardous Air Pollutants (HAPs).

They’ve been third-party tested according to EPA Method 24 and Method 311.

Vegan

We don’t use any animal products. And no animals are harmed in the manufacture of our products.

*certifications ongoing

Request a sample

Would you like to try BiobarcTM and test its barrier properties for yourself? Simply get in touch and we’ll be happy to send you a sample.

Our Impact

Why we do what we do.

Our products are created with our mission in mind–to help advance the global transition to a circular economy.

We overcome practical challenges to circularity within the paper industry.

Industry perspectives

Lars M. Ljung, Sustainability Manager at Planet Protector

Other Products*

*coming soon

*coming soon

Contact us

Whether you’re looking to improve your carbon footprint or curious about how we can be helpful for your business, we’re a call/email away.

- hello@earthodic.com

- 18 Morrisby St

Geebung QLD 4034

Australia

"*" indicates required fields

- hello@earthodic.com

- 18 Morrisby St

Geebung QLD 4034

Australia